Investments in Printing Technology and Equipment Position Colbert Packaging for Continued Growth and Leadership in 2022

Recent investments demonstrate Colbert’s commitment to innovation and sustainability

Kenosha, WIS – Colbert Packaging Corporation (colbertpkg.com), a leading Midwest paperboard packaging manufacturer, reports that recent investments in printing technology and equipment are evidence of working a strategic plan to satisfy secondary packaging needs of pharmaceutical and consumer healthcare manufacturers in North America.

At a time when many firms have scaled back investments due to economic uncertainty, Colbert Packaging has demonstrated industry leadership by its continued investment in printing technology and equipment for sustainable paperboard packaging.

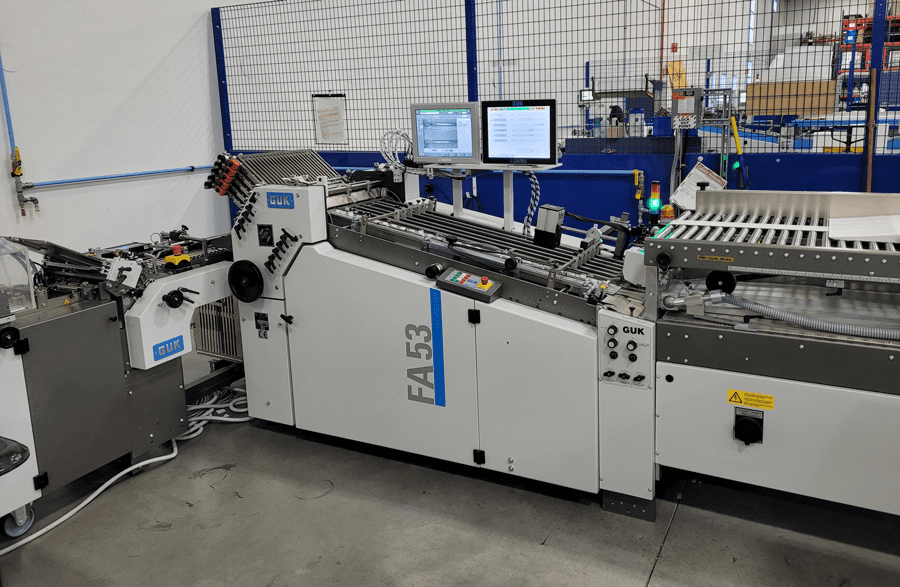

For example, the new outsert folder and tabber tackle complex pharmaceutical inserts/outserts with patented folding procedures. The folder produces RTA (right-turn-angle) cross-folded outserts. The tabber complements Colbert’s secondary packaging capabilities, bringing more specialty packaging functions under one roof, an added benefit for compliance with stringent customer audit requirements.

The recent addition of a vision inspection system in the Elkhart, Indiana location means all Colbert Packaging operations are 100% vision inspection capable, enabling defect detection without disrupting the production run—an important distinction for pharma and consumer brand managers.

Other ancillary support equipment added in recent months:

GenieCut inline windowing equipment gives customers the added benefit of product visibility within the folding carton. The GenieCut technology is unique in that it eliminates glue pots, allows for custom application of adhesive, and applies a film window to the carton inline on the folder-gluer.

For protection against product counterfeiting and improved efficiency, Colbert has added the ability to serialize folding cartons with customer-specific sequential data.

“This is particularly valuable to our pharmaceutical and healthcare customers,” states Colbert Packaging President John Lackner. “The growing concern and demand for serialization played into our strategic plans for growth, and there will be more news to come about our continued investment in printing equipment designed to increase capacity and offer our customers even more internal capabilities.”

To ‘wrap it up,’ Colbert acquired a PackSize® box making machine for each location. Custom shipping boxes represent a sustainable solution by generating less waste and lowering shipping costs.

Lackner concludes, “As a leader in the secondary packaging industry, these capital investments demonstrate a significant commitment to our customers, employees and suppliers. We are well-positioned to work together into the future.”

Colbert Packaging Corporation is a family-owned business with extensive R&D capabilities and a solid reputation for excellence. Founded in 1959, Colbert Packaging has grown its repertoire of paperboard packaging solutions into one of the most comprehensive, diverse and inventive portfolios in the industry. Colbert’s Kenosha, Wisconsin facility produces offset and flexographic printed folding cartons, pressure-sensitive roll labels and package inserts; the Elkhart, Indiana operation includes folding carton production and paper tray forming. Learn more at www.colbertpkg.com